When supporting Series A Technological Startups or even large companies launching a new technological product, we recommend three well-defined ramp-up phases to guarantee a smooth market launch. In the first phase, called EVT for Engineering Validation and Testing phase, there is no tooling, extensive use of 3D printing is done and the result is a working prototype and a final BOM to finalise details of the supply chain and fabrication.

In the second phase, called DVT for Design Validation and Testing phase, optimized PCBs designs are used, and the design is sufficiently finalized to do testing and certifications, and samples can be sent to partners and customers for opinion and testing.

In the third phase, PVT for Production Validation and Testing, products are made in mini-production runs, typically 5-10% of the standard batch run, and by then the manufacturing package is finalized, production metrics are measured and the final production layout is optimized.

These three phases are further defined below:

Production Scaleup Support phases

1. Engineering Validation and Testing Phase

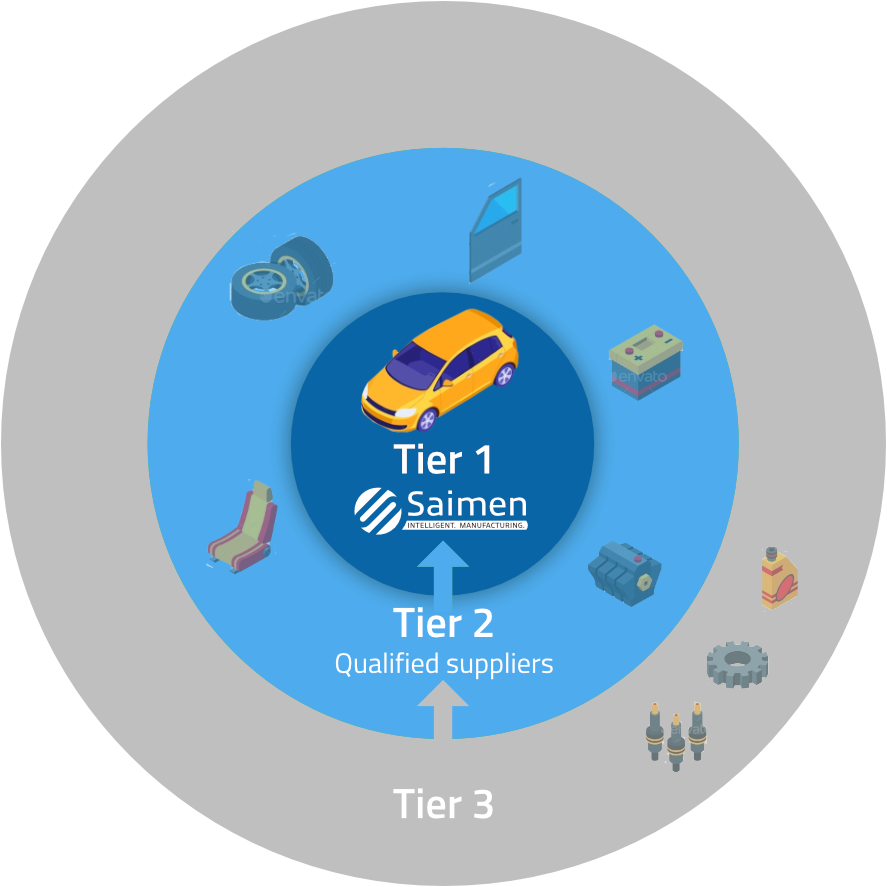

During the Engineering Validation Phase (EVT), the sourcing and assembly strategies are defined, covering up tiers 1, 2 and 3, including the incoming inspections between tiers.

The assembly of the first units are generally done at the partner’s site or Saimen’s site in Montreal, with full collaboration of the partner’s technical team. Those units should be tested by the partner and by users.

The parts and sub-parts will come from Tier 2 suppliers that will have been identified and primarily qualified by Saimen. They, in turn, might use subparts coming from Tier 3 suppliers that will be approved and primarily qualified by Saimen when those subparts are critical. A stronger qualification of all those suppliers will be done once parts will actually be used in the unit assembly. Price reduction opportunities should be contemplated, such as finding electronic components equivalences, PCB final redesign, etc.

The objective of this the EVT Phase is to

- Finalize Design for Manufacturing

- Qualify the suppliers of Tier 2, and also Tier 3 when applicable

- Validate the assembly and sub-assembly process

- Produce units that can be tested in the field

- Confirm the Tiers 1 and 2 incoming inspection criteria’s and process

- Start to identify the price reduction opportunities while maintaining quality

2. Design Validation and Testing Phase

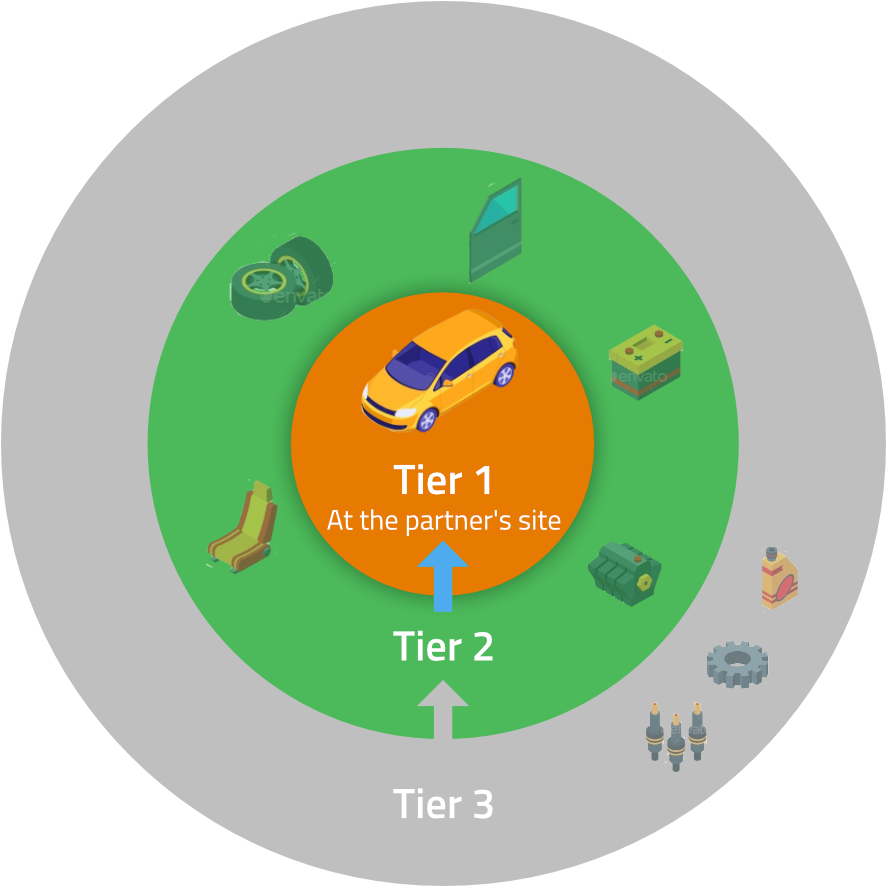

During the Design Validation Phase (DVT), the assembly of more units will be done at the partner’s site or Saimen’s site in Montreal, with parts coming from Tier 2 and Tier 3 suppliers that will have been qualified after having verified and used the parts received in the 1st phase.

The units produced in this phase will be similar to the ones to be mass produced; they should be tested on the field by typical users.

New components selected for cost reduction should be used.

The objective of this DVT Phase is to:

- Design “Function testing package”

- Confirm the quality of the parts and sub-parts coming from Tiers 2 and 3, and of the equivalences.

- Validate the assembly process based on lessons learned in the EVT Phase, including Manufacturing and Assembly procedures.

- Do production tools design.

- Produce units to be tested in the field.

3. Production Validation and Testing Phase

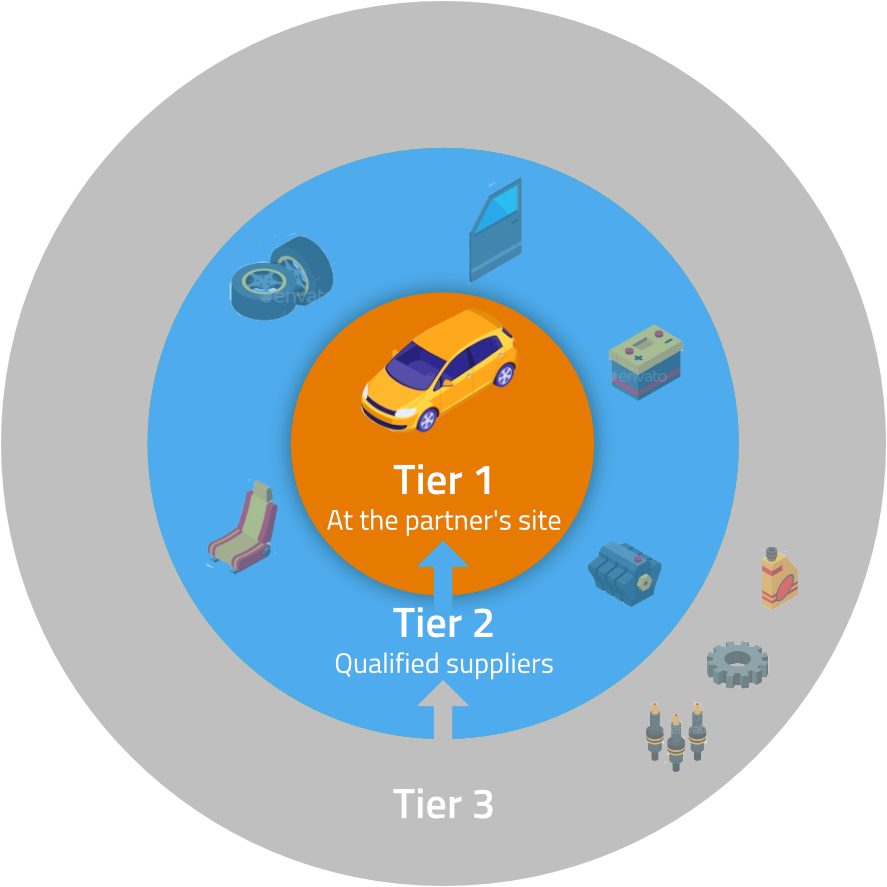

During the Production Validation Phase (PVT), units will be assembled by Saimen, with parts coming from the same Tier 2 and Tier 3 suppliers that will have been qualified during the DVT Phase.

The units produced in this phase will be similar to the ones to be mass produced, however in smaller quantity in order to test the whole assembly process and the final quality.

The objective of this PVT Phase is to

- Move the final assembly process to the production site

- Validate the whole production process

- Confirm the quality of the units produced

- Optimize yield and capacity

- Proceed to certification testing